The HELENUS project will demonstrate high efficiencies, low emissions, and novel and integrated designs of solid oxide fuel cell (SOFC) systems in maritime applications. The contributing key outcomes of the project are elaborated below.

Demonstration of a TRL7 SOFC solution onboard a cruise ship

The HELENUS consortium will install and demonstrate a 500 kW SOFC module onboard an MSC World Europa class cruise ship. With the SOFC system being installed in the machine area of the ship, HELENUS will enable the complete integration of the novel energy system within the ship design. This solution will be based upon the best compromise between compactness, weight and performance, and will also enable modular SOFC stack replacement and refurbishment during nominal maintenance intervals. Installation in a permanent location not only ensures seamless- and uninterrupted- ship operation, but also enables optimal waste heat recovery and future upscaling of the SOFC modules within the ship energy system.

Establishing the basis for achieving TRL 8 for high-power fuel cells

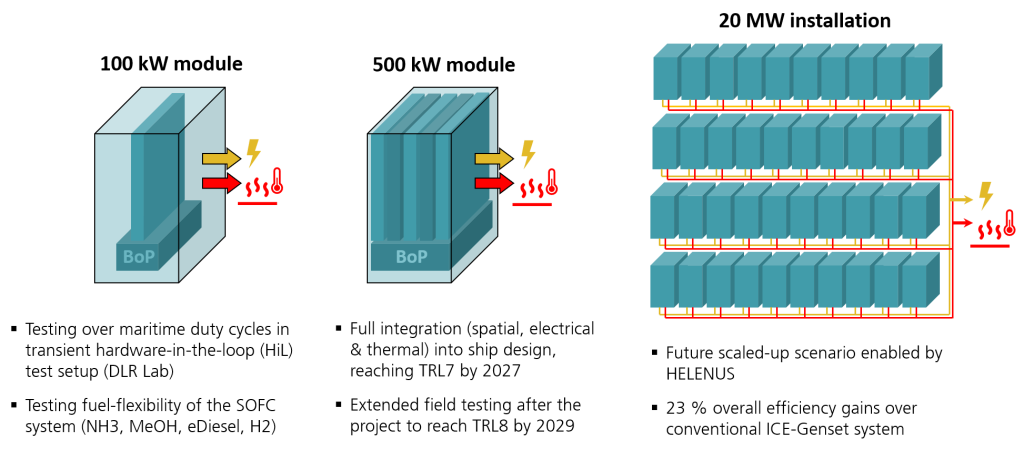

HELENUS will create a pathway to reach TRL 8 for cruise ship applications by 2029, through extended field testing after the end of the project. Through data collection and publication even after the project, the HELENUS partners will demonstrate its performance over extended operation. The SOFC module will also be ready for class approval at the end of the project, creating a blueprint for upscaling the SOFC system to 20 MW within future cruise ships.

Cogeneration (combined heat and power)

The SOFC module will operate in cogeneration (combined heat and power) mode, producing both electrical and thermal energy for onboard use. SOFCs demonstrate cogeneration efficiencies as high as 85%, which is significantly higher than state-of-the-art ICE Gensets. This is because SOFCs reject heat at high temperatures, which is easily harnessed in the form of pressurized steam. This not only enhances the overall efficiency of the SOFC module, but also reduces the need for additional onboard steam generation through boilers, thereby enabling further fuel savings. The HELENUS consortium will also investigate heat recovery through advanced thermodynamic cycles, such as the Organic Rankine cycle, steam turbine cycle, and absorption chillers, for future system designs.

Ultra-high system efficiencies

The HELENUS SOFC module will achieve ultra-high system efficiencies compared to state-of-the-art energy converters. The developed SOFC module will achieve electrical efficiencies over 60% and cogeneration efficiencies close to 85%. The high cogeneration efficiencies more than halve the energy losses from the system, in comparison to ICE Gensets. Scaling up the SOFCs to 20 MW will increase the overall electrical and cogeneration efficiencies by as high as 24%, translating to a corresponding reduction in CO2 emissions.

Scalability

The 500 kW HELENUS SOFC module installed onboard the MSC World Europa class cruise ship will serve as the building block to scale up the fuel cells to as high as 10-20 MW in the future. In such an energy system, the SOFC modules will supply all the hotel loads and a portion of the propulsion loads, enabling the utilization of fewer or smaller ICE Gensets. To achieve this, advanced energy management and transient control algorithms will be developed and demonstrated under laboratory conditions to showcase the potential of SOFC system scale-up.

Greenhouse gas emissions reduction

The SOFC module has significant potential for reducing greenhouse gas (GHG) emissions, in addition to improving system efficiency. Methane slip, which is a significant contributor to GHG emissions, can be almost entirely eliminated by the SOFC module. This is important because methane is a highly potent GHG — 86 times higher than CO2 over a 20-year horizon. By reducing methane slip, the SOFC module can contribute significantly to the reduction in GHG emissions. Furthermore, SOFCs also almost completely eliminate other harmful emissions, such as NOx and SOx, as well as black carbon, which are detrimental to both human health and the environment.

Applicability over a range of maritime applications

HELENUS will demonstrate the applicability of the SOFC module across various maritime applications, including dredgers and offshore vessels. Unlike cruise ships which have stable and steady hoteling load demands, other maritime applications have more dynamic load demands. This requires advanced transient controls and energy management algorithms, even for smaller SOFC sizes. Ship design and space availability also impact the applicability of SOFCs for these applications. HELENUS will use a combination of simulation and experimental techniques to optimize the SOFC sizing and configuration, and demonstrate the corresponding fuel efficiency and emissions benefits over representative duty cycles. The generated experimental data will provide realistic predictions of SOFC performance and operability across different maritime applications.

Fuel flexibility

While LNG is currently the cleanest fossil fuel available, the maritime industry will move to renewable and carbon-neutral fuels in the near-future. Since ships have long service lifetimes, onboard energy systems must be capable of operating with a wide variety of future maritime fuels. SOFCs are inherently compatible with different fuels, including LNG/methane, methanol, ammonia, hydrogen, and more, without requiring energy-consuming reforming apparatus. HELENUS will experimentally demonstrate the fuel-flexibility of the SOFC module with other renewable fuels, which is crucial for ensuring the readiness of shipping for future fuel transitions.